Double

Introduction: Banana screen also called equal thickness vibrating screen. KMD banana sieve adopts international advanced

Basic Info.

| Model NO. | 2LKBB2461 |

| Running Track | Linear Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Site Service |

| Transport Package | Bulk Shipment |

| Trademark | Landsky |

| Origin | China |

| HS Code | 84741000 |

| Production Capacity | 100 |

Product Description

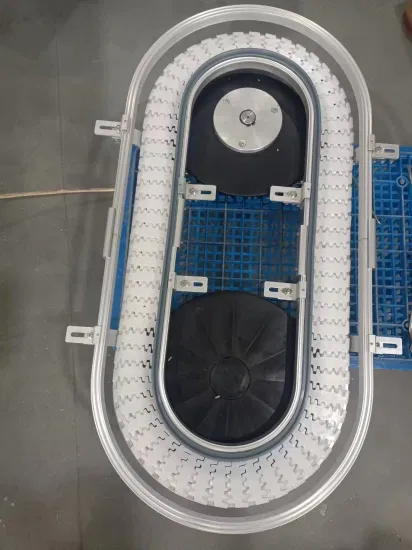

Introduction:Banana screen also called equal thickness vibrating screen. KMD banana sieve adopts international advanced design concept, processing technology and testing technology. According to the principle of equal thickness screen surface, the continuous multi-angle screen surface design (usually composed of three Angle, five Angle and seven Angle) is adopted. It has the advantages of high stability, large handling capacity and long service life.KMD banana screen can handle 2 to 3 times of the traditional vibrating screen per unit area. Banana sieve is widely recognized by users for its large processing capacity, high screening efficiency, stable and reliable performance.Feature and Advantage:Engineered up to 4.3m in width and 9.7m in lengthUsing the principle of equal thickness screening design, international advanced screening technology and processing technology;Screen surface continuous multi-angle design, with high stability, large capacity, long service life and other advantages;Independent research and development and manufacturing of key core components, stable operation and small maintenance;Product diversification, there are three types of single deck, double deck and triple deck;The difference between decks of double screen surface is 1.2m, convenient to replace the screen plate;The screen plate is made of polyurethane or rubber material, and a variety of holes are selected.Cloud intelligent monitoring system for vibration parameters (optional);AH36 ship plate is used for side plate, wear resistant and anti-corrosion paint is used for equipment surfaceHigh throughput per screening areaExcellent sizing efficiency due to rapid stratification of finesAll-bolted construction using locking bolts to ensure structural integrityWear-resisting rubber installed to protect the machinery during highly corrosive applications and lower the total cost of ownershipApplication:Primary sizingSecondary sizingTertiary sizingHPGR discharge screeningMill discharge screeningDe-slimingWashingService:KMD Banana screen is a custom solutionOur banana vibrating screens fully cover existing international specifications and can vary according to your current factory layout and handling capacityEach application site has specific requirements - To ensure that the screen machine is exactly right for your specific field application and reduce the risk of maintenance requirements or failures, each of our screens can be specially customized to optimize existing processes or match parameters for new projectsDon't compromise on the original size, create a unique screen for your site and team.previous:

Double Layer Banana Vibrating Screen

Banana Screen :next

Send to us